Bitumen is one of the most used materials in the world. As infrastructure expands, so does the demand for virgin asphalt and aggregates increased. However, many countries have problems obtaining raw materials, especially petroleum bitumen. Therefore, the use of recycled asphalt will be the trend. Governments are also increasingly looking to reuse bitumen recovered from old roads in pursuit of being more environmentally friendly.

Asphalt recycled materials are mainly collected from old materials milled by road milling machines, crushed with asphalt recycling granulators, processed and screened into different sizes required, and then combined with regenerants, new asphalt, new aggregates, etc. Re-mixed into a new mixture according to a certain proportion, and re-paved to the road surface. Asphalt recycle material can be recycled through our asphalt recycling equipment. Asphalt recycling technology can save a lot of raw materials such as asphalt and sand, and at the same time, it is beneficial to waste disposal and environmental protection.

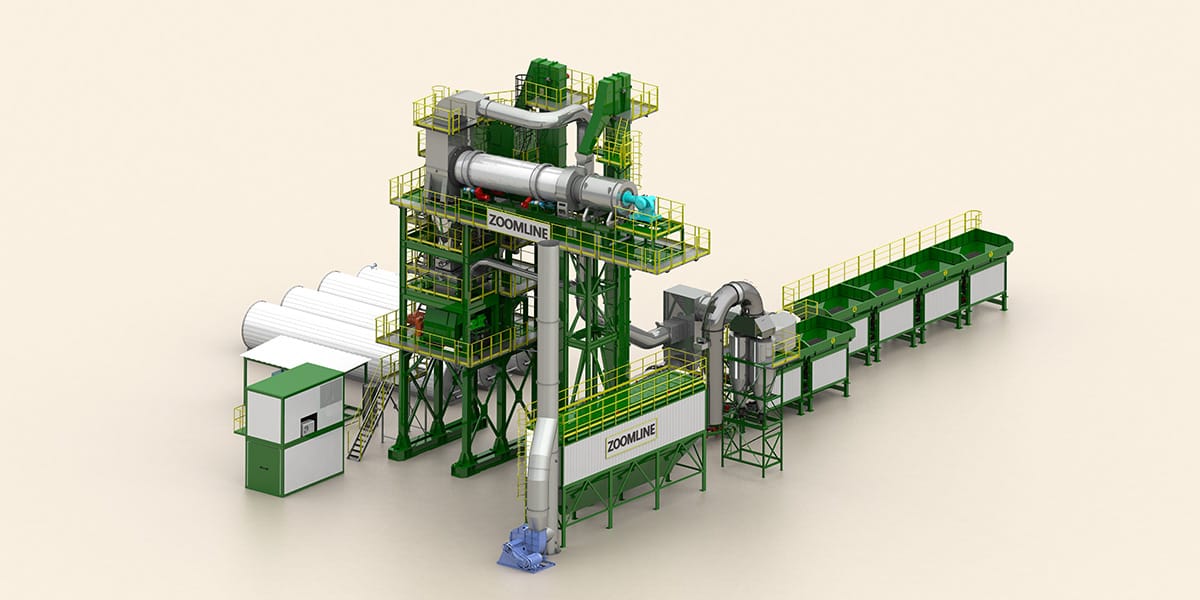

ZOOMLINE provides a wide range of hot and cold asphalt recycling equipment design solutions to help you recover asphalt better and save costs. Regeneration technology can be individually tailored or integrated into existing asphalt plant retrofits.

Hot Recycling Plant

Hot Mix Asphalt Recycling Plant is to transport the old asphalt pavement back to the mixing plant after excavation, and crush it in a centralized manner. According to the quality requirements of different layers of the road surface, the proportioning design is carried out to determine the addition ratio of the old asphalt mixture. Asphalt materials, new aggregates, etc. are remixed into new mixtures in a certain proportion in the mixer, so as to obtain excellent recycled asphalt concrete, which can be paved into recycled asphalt pavement.

Cold Recycling Plant

Cold Mix Asphalt Recycling Plant is to transport the recycled asphalt pavement materials to the mixing plant. After crushing and screening, they are mixed with new aggregates and active fillers in a certain proportion. The water is mixed at room temperature, and the asphalt pavement regeneration technology is paved at room temperature to form the pavement mechanism layer. It is mainly used for the base or sub-base of high-grade highways. For old materials that cannot be regenerated by heat (such as modified asphalt mixtures, mixtures that are seriously aged and difficult to regenerate), it can effectively solve the problems of waste of old materials and environmental pollution.

Features

The mixing main engine is placed on the regeneration building, which changes the traditional heating mode of recycled materials. The structural design is novel. The integrated design of the original station and the regeneration station increases the proportion of recycled materials and increases the output.

The regenerated drying drum has a unique shape, and the scraper prevents material sticking to the greatest extent. The production is efficient and stable, and the maintenance is safe and easy.

The high-temperature exhaust gas returns to the drying drum through the return flue for reuse, saving energy and reducing the burden on dust removal equipment.

The proportion of old materials added in this regeneration method reaches 30%-80%.

ZOOMLINE asphalt plants enjoy a high reputation as the excellent quality, perfect performance and unparalleled service. We have also established and upgraded the production technology of recycled asphalt mixture, and the recovery rate is 40% to 50%.

If you want to get more information about the configuration, latest price and product parameters of our asphalt recycling equipment , please feel free to contact us. Our professional engineers and sales will provide the most reliable advice, the most suitable plan and the most reasonable quotation for your reference!